Project Overview

Problem:

With rising fuel costs, there is a need for higher efficiency boat propulsion systems. Walvisstaart B.V., a company from the Netherlands focusing on boat propulsion systems, approached Thayer school seeking experimental data to evaluate the efficiency of their design. They also wanted to compare this data to theoretical predictions made by an existing computational fluid dynamics (CFD) model. Walvisstaart had already spent over $250,000 on engineering consultancies and several years attempting to accomplish these goals by the time they came to Thayer. Once involved with Thayer, the effort was designated a capstone project for candidates of the Bachelors of Engineering in Mechanical Engineering (BEME) degree. Two groups of students in previous years had tried and failed to obtain the necessary measurements to accurately assess the efficiency of the system.

Solution:

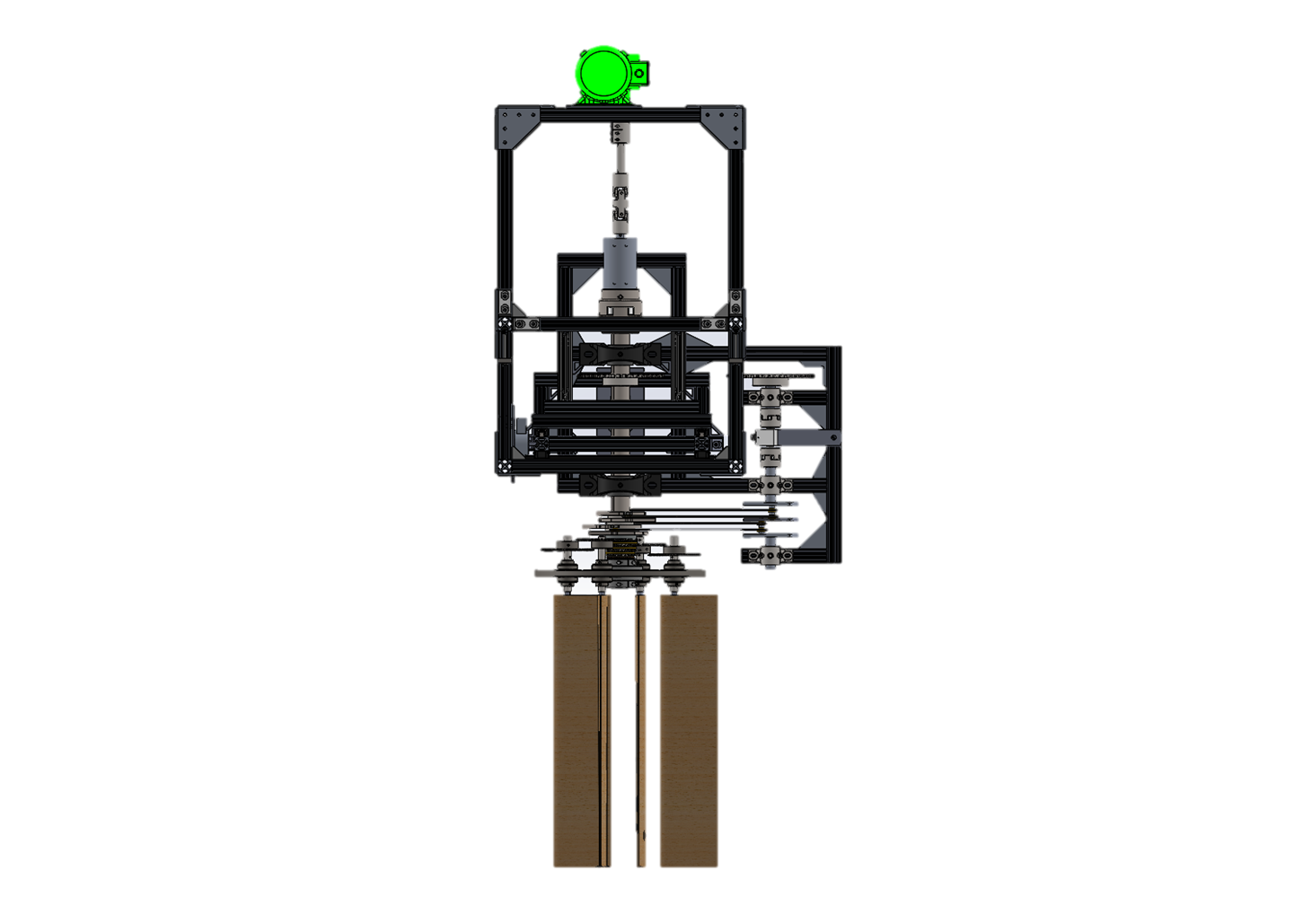

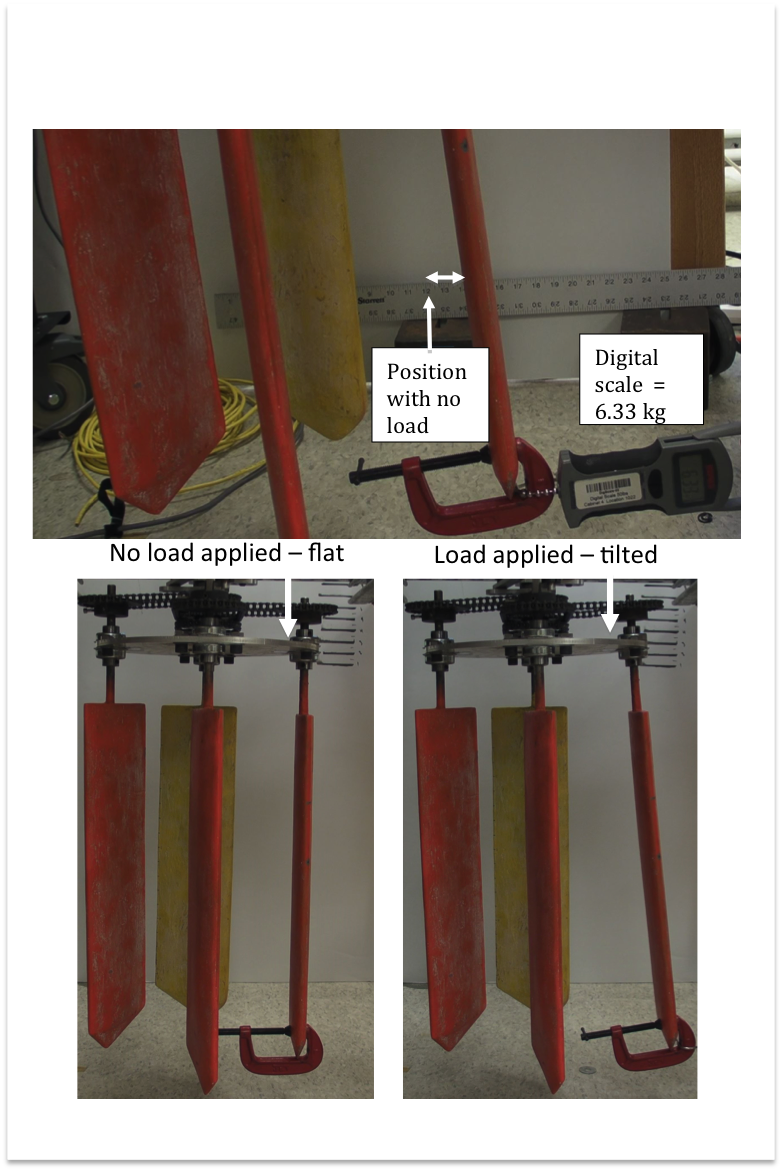

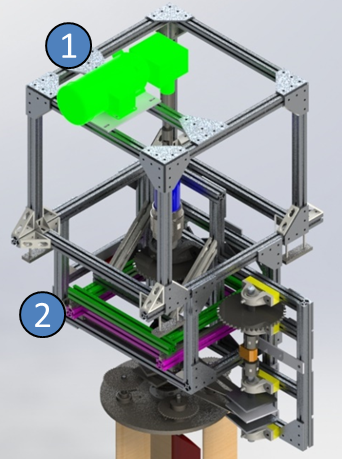

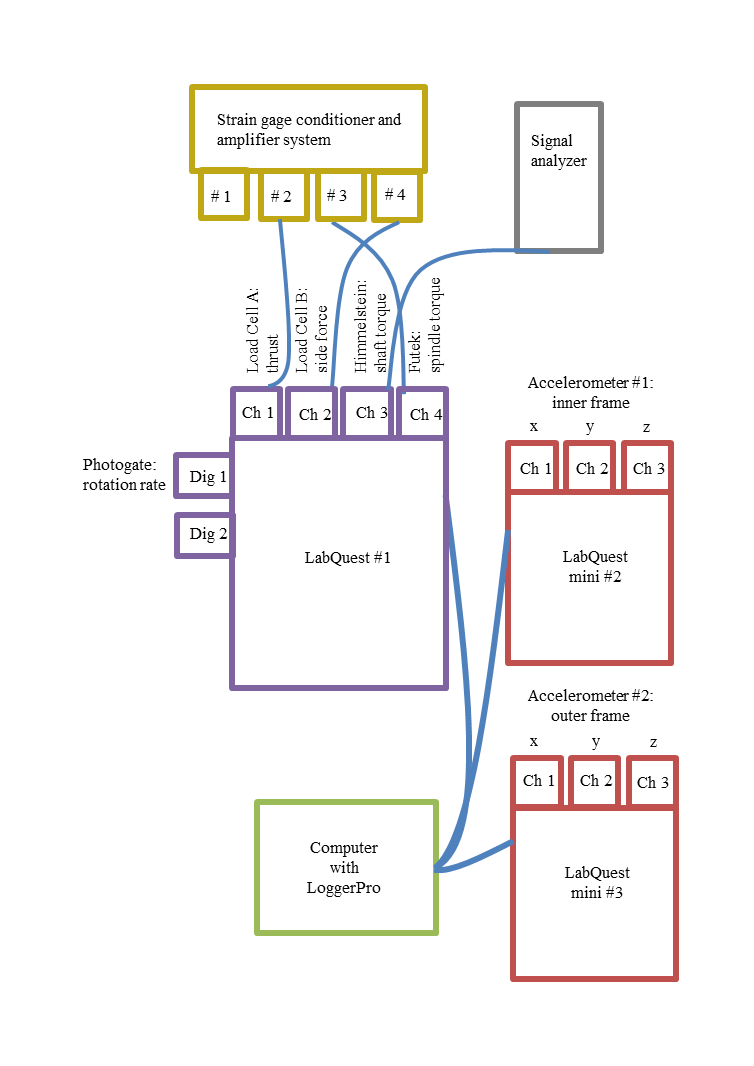

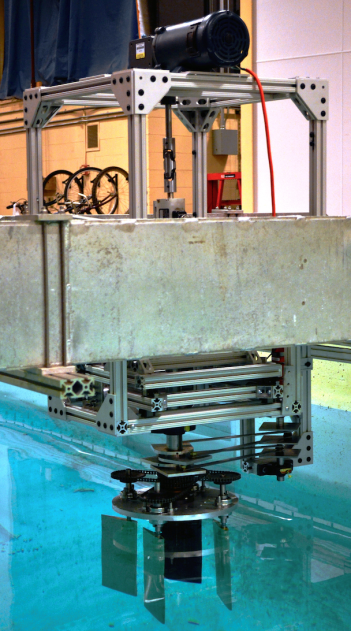

Using the past Thayer students' prototypes as a starting point, four other BEME candidates and I redesigned the Walvisstaart testing machine and successfully obtained the necessary data. The majority of our redesign effort focused on the drive shaft, motor positioning, and rail system of the product, but in total the effort included machining 55 parts in house, and purchasing 212 more to create our final 267 part assembly. I spearheaded the analysis of the drive shaft, performed a large portion of the machining and assembling of the product, and was responsible for all of the computer aided design associated with the effort. At commencement, our team was awarded the John C. Woodhouse Engineering Design Prize "in recognition of outstanding economical and creative design" on this project.

Design Process