Project Overview

Problem:

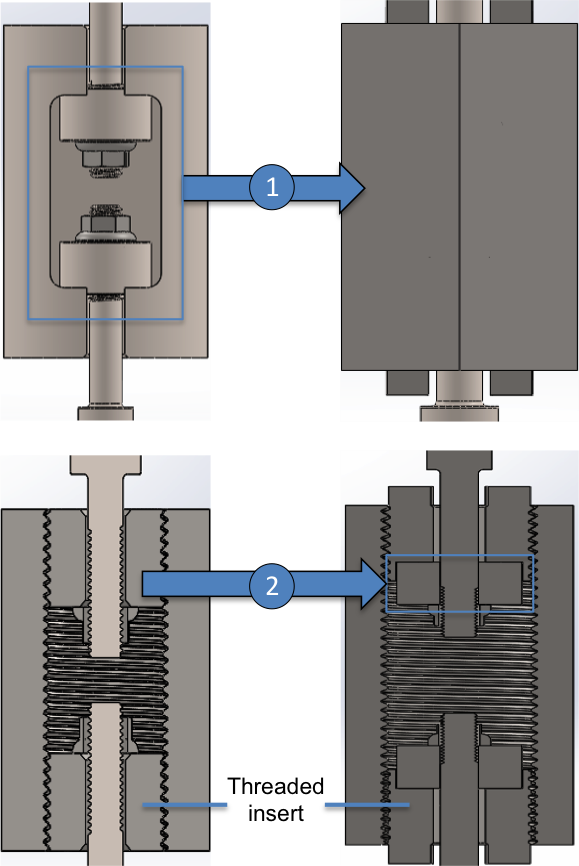

Maclean-Fogg was spending $40,000 annually to get an independent lab to stress embrittlement test their nuts in order to comply with a government specified “External Loading” method. It required that 10 nuts be under a load equal to 80% of their rupture load for 23 consecutive hours. Maclean-Fogg wanted to buy their own machine to do the job, but outside quotations came in at $200,000.

Solution:

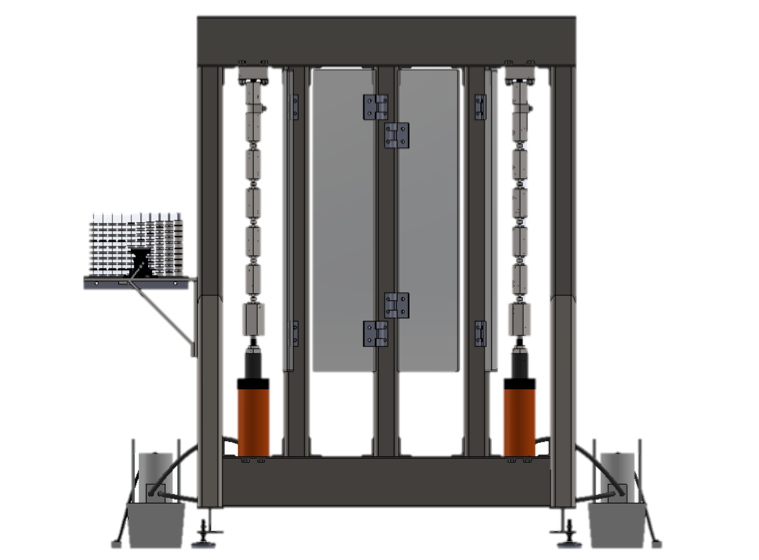

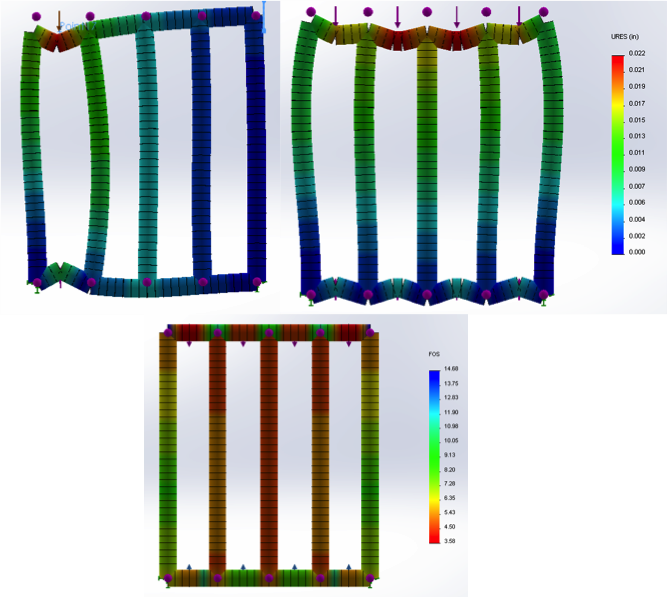

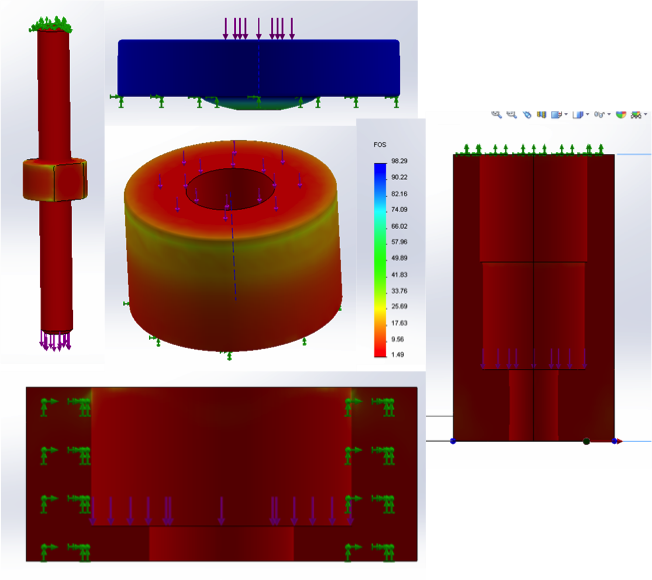

During a two month summer internship I designed and built a test machine for $20,000 that could automatically record and regulate the load on the nuts up to 50,000 lbs via a load cell that communicated with a hydraulic system. I designed the machine to be expandable in the future to meet the needs of increased business. I did FEA on the frame and parts in order to ensure a large safety factor, while optimizing the material for the lowest cost. I produced G-codes for the lathe using a CAM program to quickly manufacture the parts. MacLean-Fogg is now using the machine for nut quality testing.

This machine is currently awaiting NADcap accreditation for aerospace quality testing.