Project Overview

Problem:

In 2013 alone, 8.3 billion K-cups were produced, which is enough to wrap around the equator of the Earth 10.5 times. Due to the combination of #7 plastic, a paper filter, an aluminum lid, and ground coffee inside the cup, it is not recyclable. All of the components end up in landfills, despite all of them except the plastic cup being individually recyclable or compostable. Not only are K-cups bad for the environment, they are also expensive costing consumers around 68 cents per cup vs. 44 cents per cup from bagged beans. 54% of Americans over the age of 18 drink at least three cups of coffee each day, on average, and because of its convenience the Keurig machine has dominated the market for these coffee-drinkers. We sought to design a coffee machine that would utilize bagged beans to enhance its sustainability, but would clean itself in order to provide the convenience that consumers expect and desire.

Solution:

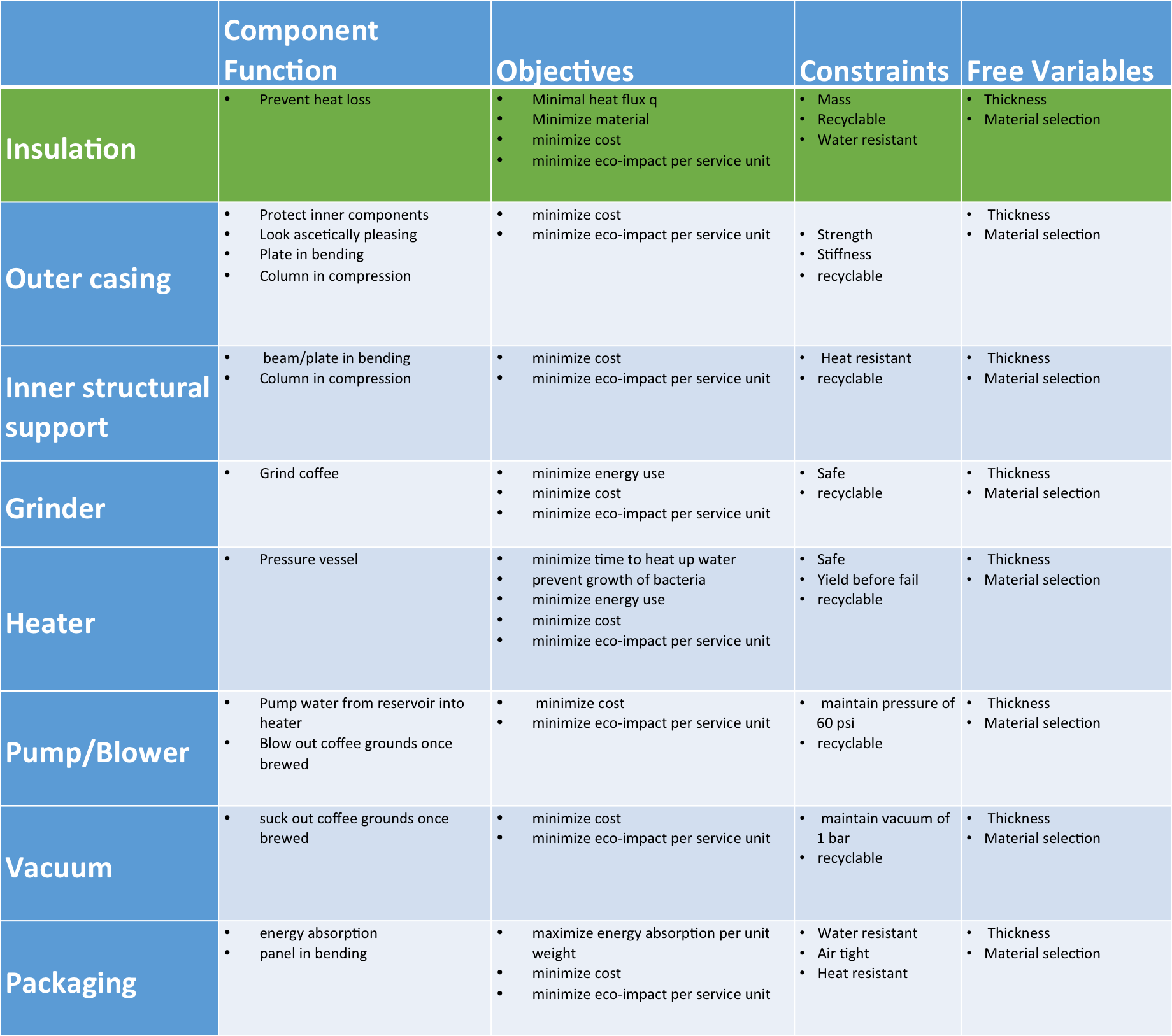

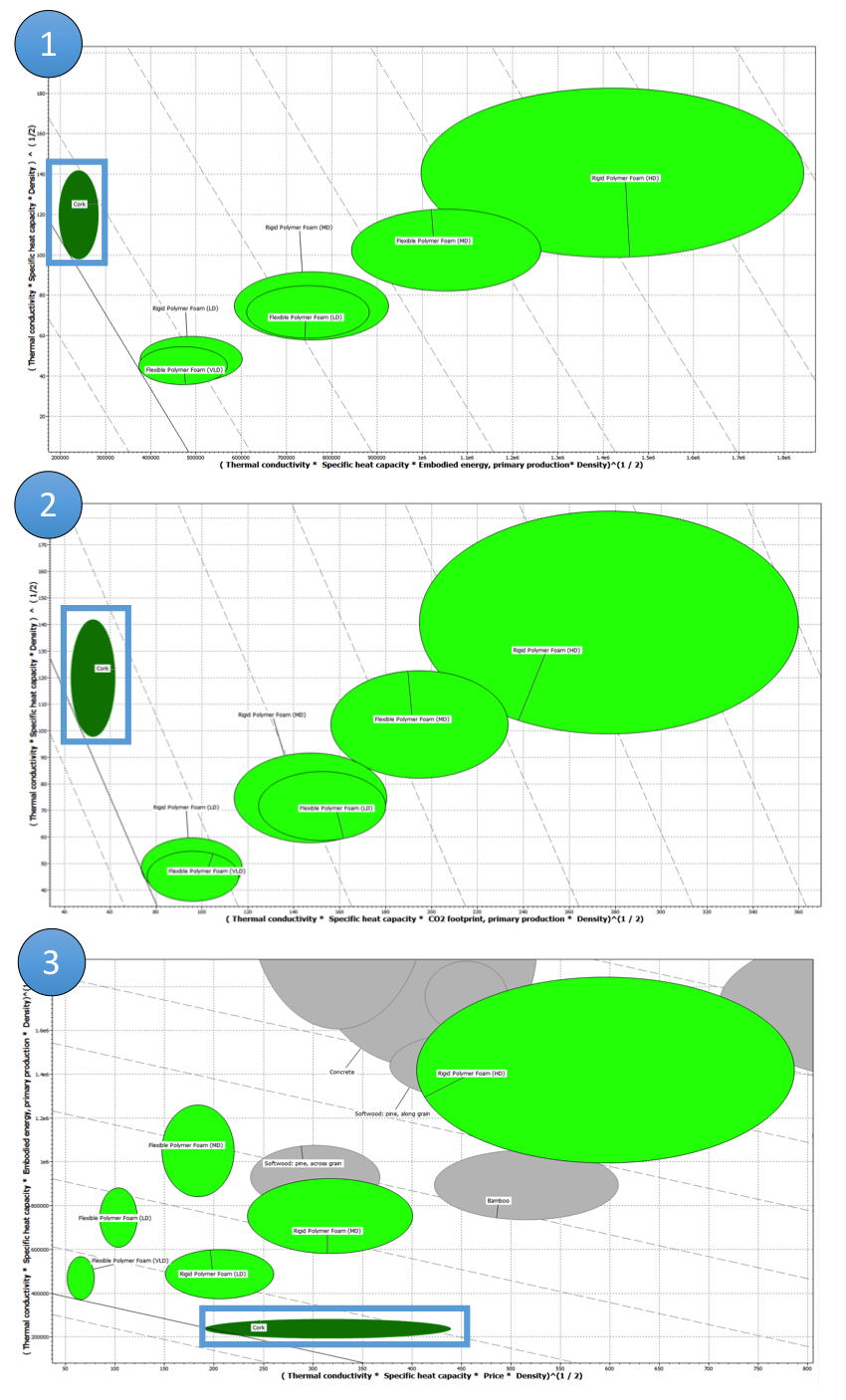

As part of an Industrial Ecology class, a teammate and I deconstructed the Keurig machine to learn about all of its parts and mechanisms. We then performed an "EcoAudit" on the machine's components to determine its energy requirements, water usage, and carbon footprint, and re-designed it to be more sustainable. The key components of our re-designed coffee machine were a bamboo casing, cork insulator, and a self-cleaning system to allow for use of unpackaged coffee grounds. I earned a citation for academic excellence in the class, for "excellence throughout the course: active participation in class discussions, high quality assignments, and creativity and attention to detail above and beyond expectation in the term project and presentation.”

Design Process