Project Overview

Problem:

The state of the art method for bamboo construction requires power tools and is very time intensive. Given the intention of constructing bamboo homes in Haiti (see the "Affordable Bamboo House" page for details), there is need for a tool that requires less time and electricity.

Solution:

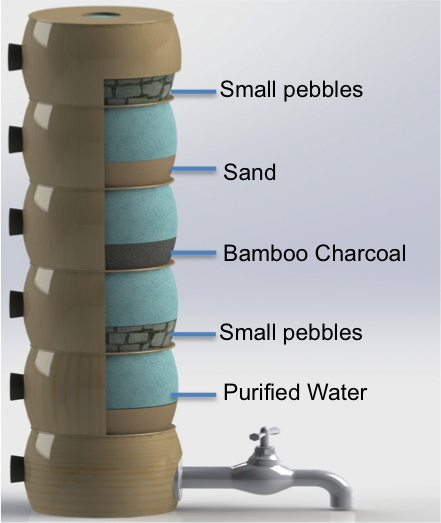

I created a manual bamboo processing tool that splits and cores the bamboo at the same time. I then created a novel way to bind the bamboo together into an interlocking section so that it doesn’t require the notching and individual wire wrapping that was very time consuming in the original roofing prototype. This interlocking bamboo section can be oriented horizontally to act as a roof, or vertically to act as a wall. Therefore, an entire house can be built using the pieces made from the bamboo processing tool. Additionally, given that 80% of ground water in Haiti is infected with cholera, I additionally designed a mechanism to collect rain water from the roof of the house. I believed that this would incentivize locals to adopt the house, which was important given the foreign nature of bamboo houses in Haitian communities.

Video of the first bamboo splitter prototype in action!

Final Prototype of the Bamboo splitter in action!

Design Process