Project Overview

Problem:

People bring sludge into buildings on the bottom of their boots, especially in the winter. The building then has to be cleaned up once the mess is spread out over hundreds of square feet. This creates a costly slipping hazard, and requires institutions like Dartmouth to hire extra janitorial staff during the winter months to help solve this problem.

Entryway of Dartmouth's Baker Library in February

Solution:

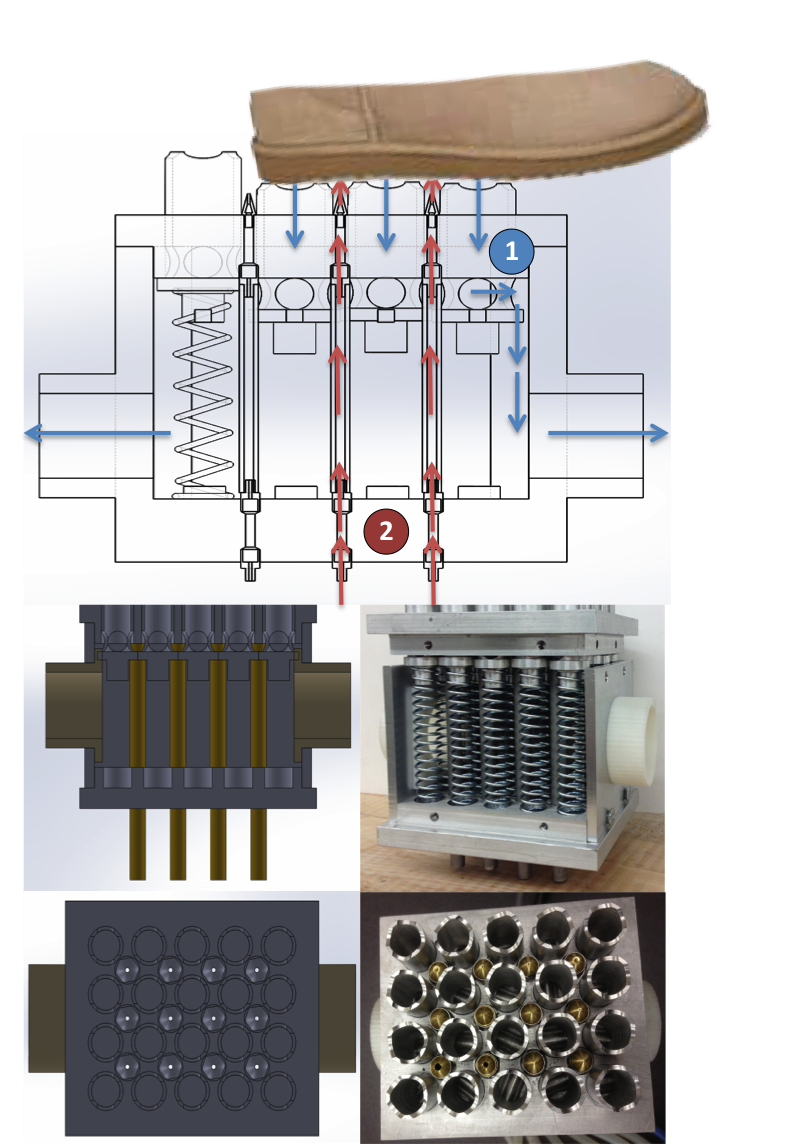

After interviewing various key stakeholders at Dartmouth, I identified unobtrusiveness as a key specification for a solution, as people entering buildings are often in a hurry and don’t have a stake in how dirty the floor gets. I designed a device to be embedded within the entryway floor (instead of the existing felt-covered grates) that simultaneously blows on the soles of shoes to dislodge debris, and vacuums it into a reservoir to keep the floor clean. My solution, The Vacuum Box, cleans off the bottom of visitors’ shoes as they enter a building, preventing sludge from accumulating indoors.

Pressure-activated vacuum box to clear sludge off shoes

Design Process