Project Overview

Problem:

The project started with the client asking us to evaluate how to make their already tooled up LED wall sconce waterproof as it failed waterproof testing. They also wanted us to redesign one of its sheet metal components into a diecast part.

Solution:

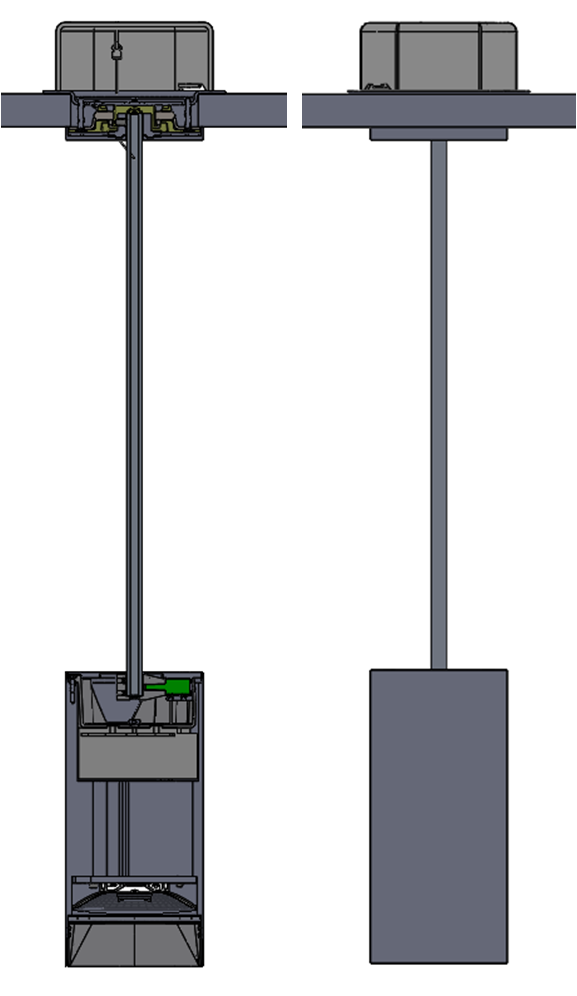

While we initially tried to reuse as many components as possible that had already been tooled up, the client eventually decided to scrap the old product's tools completely due to how much he liked our new design. Therefore, the project progressed to a full redesign of the product. Though the project started with the redesign of a wall mount sconce, the client ended up adding a stem, pendent, ceiling, and an adjustable ceiling configuration to the product line. The client also wanted a larger circular version and a square version of those same configurations. In total, the project grew to have 14 configurations. The client liked the product so much that he decided to invest in a 5-axis mill to machine the parts in house instead of having them diecast in china. This lead to another redesign as parts, which had been optimized for diecast, had to be redesigned for machining, and custom extrusions had to be made to reduce machining time. I did a complete tolerance stack up analysis and exhaustive part drawings, and am currently working with vendors in china to finalize aspects of the design that won't be made in house.